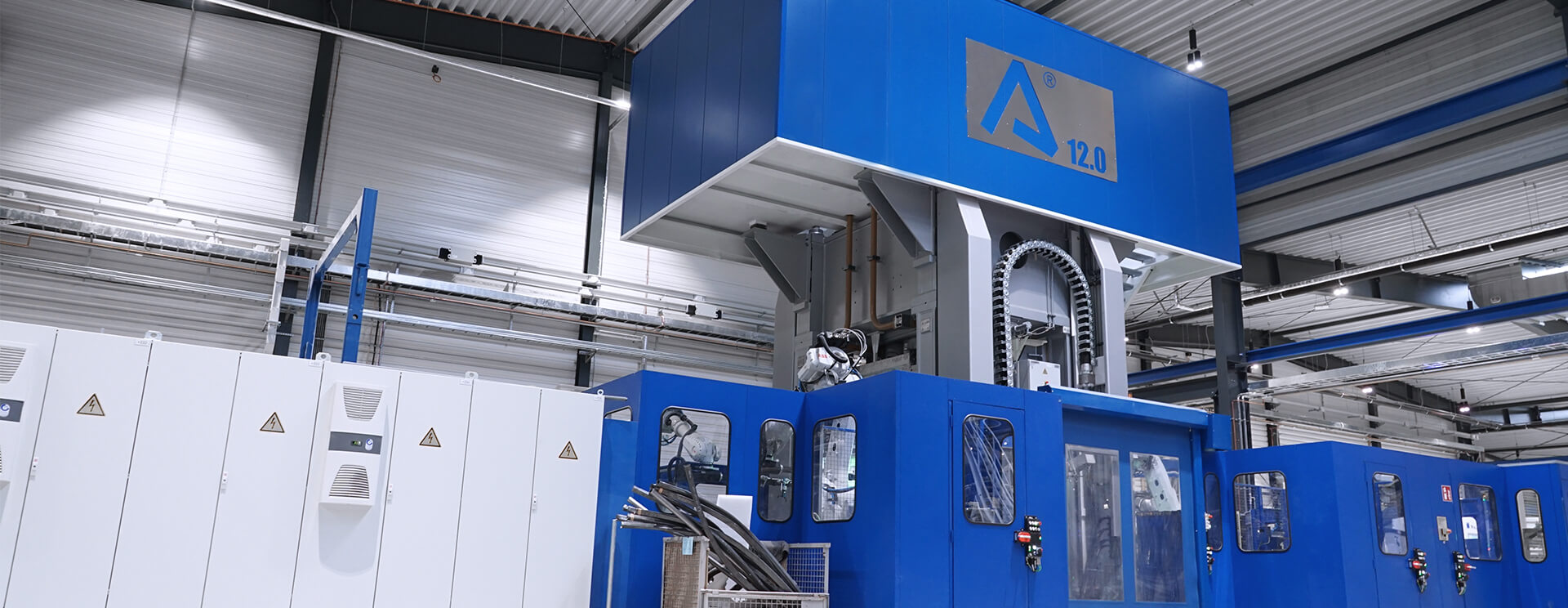

In the new workshop in Elstra, close to Dresden, the German automotive supplier LINDE + WIEMANN (L+W), with the aid of Graebener®, is setting new standards in the international hot forming business. Two new hot forming lines each equipped with a Graebener® hot forming press and an intelligent Graebener® central control form the centerpieces of manufacturing which has started the series production this summer. Since then, approximately 52,000 parts have been produced each week in Elstra, among others for example the side impact beams and A-pillars for a new middle-class car of a large U.S. automobile manufacturer. In September, the 4. generation of the new car was launched on the market.

L+W sets new standards especially by means of the ACCRA-process, a patented special application of hot forming. This process, in contrast to the regular hot forming processes, does not use plates but pipe shaped profiles as semi-finished products. In the Graebener® hot forming press these profiles are pressurized with several hundred bars during the ACCRA process and thus widened. They are aligned to the tool cavity and cooled in one single process step to adjust the material characteristics accordingly. This technology allows the production of completely or partially hardened profile-type components with arbitrary cross sections and contours. This way, components subject to extreme loads during a vehicle crash can be optimized further regarding energy absorption and weight.

Intelligent central control system ensures smooth communication

Special processes call for special technologies. Therefore, L+W again banked on the expertise of Graebener®. The family-owned machine building company has earned an excellent international reputation as specialist for sophisticated applications. In 2011, a first hot forming press was delivered to L+W in Dillenburg, the headquarters of the automotive supplier. "We have been cooperating closely and successfully with Graebener® for many years. The exceptional reliability of the machines and the vast experience, especially regarding prototyping lines and central control, were the deciding factors for placing the order with Graebener again", Dennis Fuß, Manager of the hot forming technology at L+W explains.

The two new Graebener® hot forming presses are completely identical. Each press has a closing force of up to 1,200 tons and is equipped with nine CNC controlled tool axes to do justice to the complexity of the ACCRA process. Two tool change tables per press ensure a quick and safe tool change. The smooth communication between press, high pressure unit, furnace and automation is effected via the intelligent Graebener® central control which also allows a transparent material tracking during the entire process.

The large-scale series production for the new middle-class car will continue for approximately six years at L+W. The plans for the new workshop in Elstra however, go far above and beyond this.

Return to news overview