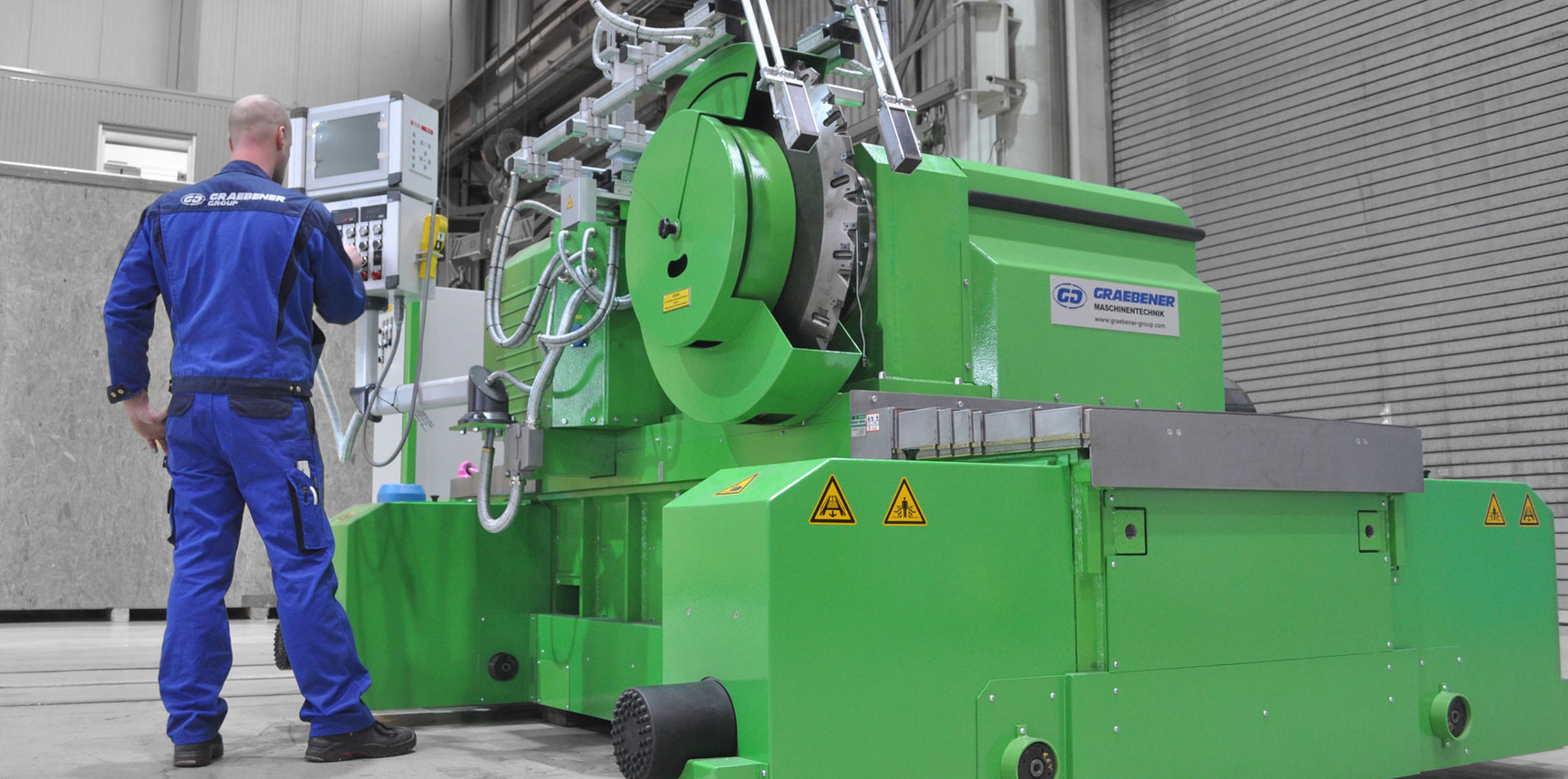

Another major global player of onshore and offshore constructions banks on the market leading milling technology of Graebener®. For the wind tower production at the new workshop, Graebener® just booked the order from the major Spanish company for one 55 kW long seam milling machine and two 55 kW circ seam milling machines – including the option of a third circ seam milling machine. Due to the increase of incoming orders for the Spanish company, Graebener® committed to deliver the machines to Spain by December 2018.

Great ambitions, great requirements

The Spanish company intends to stake their place among the internationally leading onshore and offshore manufacturers. For this purpose, the company invested several million Euro in the new location which is to manufacture several hundred sections of offshore wind towers per year starting in 2019.

Ambitions are running at the same level as the requirements and expectations of the Spanish company regarding the new production technology. The individual sections with a wall thickness of up to 130 mm and a diameter of up to 10.5 meters must meet highest requirements and most stringent quality specifications.

Therefore, the company for wind tower construction banks on the world market leader Graebener® when it comes to the weld seam preparation of longitudinal and circumferential seams. Not only can the Graebener® seam milling process eliminate errors almost completely, the costs per meter of weld seam can also be reduced by more than 50%. The technology provides three major advantages: First and compared to conventional processes, less time is needed thanks to milling speeds of up to 600 mm per minute. Second, the Graebener® seam preparation allows an automated submerged arc narrow gap welding. Third, the milling geometry reduces the cross section volume by 50% which also reduces the volume of required welding wire by 50%. This means considerable energy conservation and leads to a significantly improved process capability.

More and more Global Players benefit from Graebener® Milling

Apart from the Spanish company, more than 100 customers worldwide already benefit from the Graebener® milling technology. In the sector of offshore manufacturing the most important global players from Europe use the well-proven Graebener® technology. And very soon, this new customer from Spain will also establish a prominent place among them.

Return to news overview