Plate Edge Milling Machines

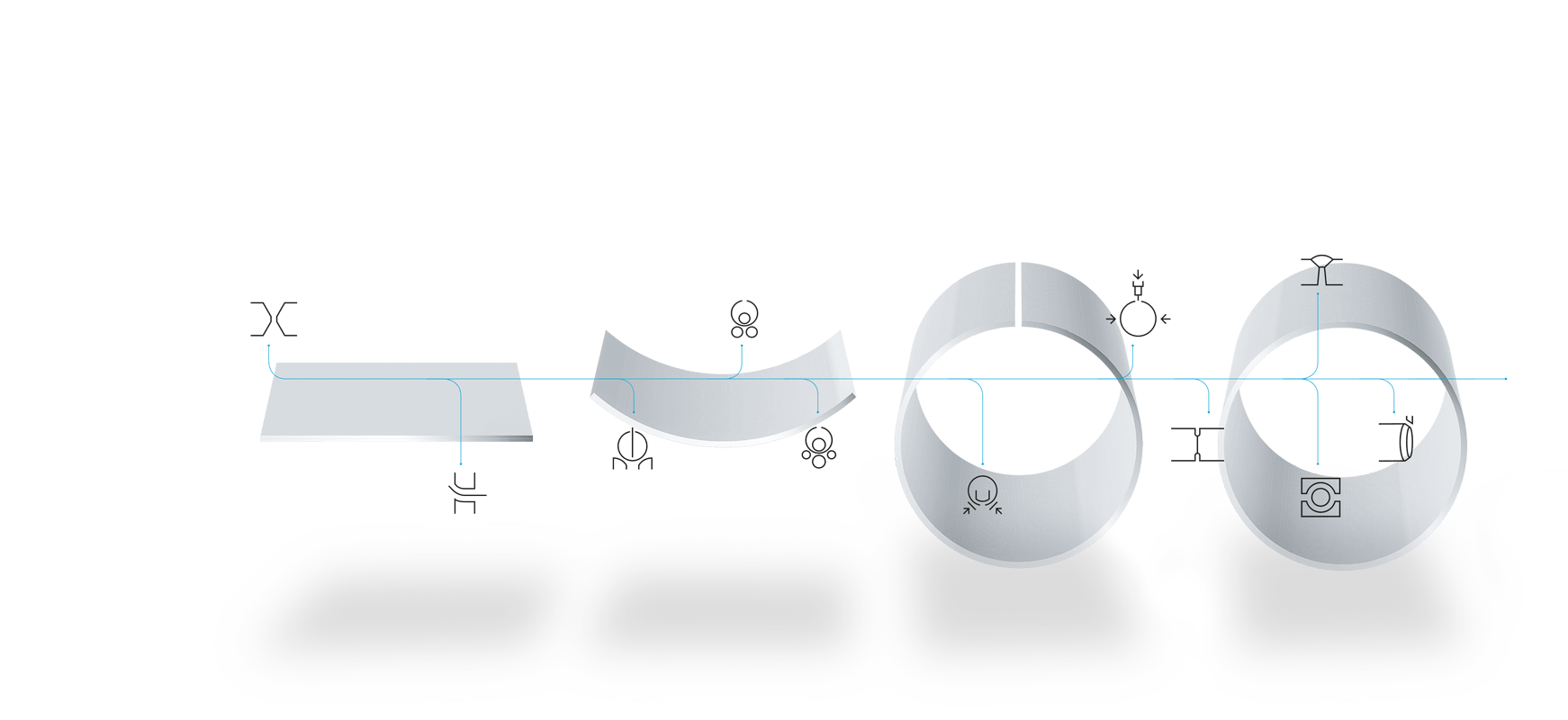

An optimum welding result requires an optimum plate edge preparation. Graebener® plate edge milling machines offer an efficient and economic solution for optimum results. Benefit from our decades of know-how and realize all common seam geometries – fast, exact and reliable.

Learn more