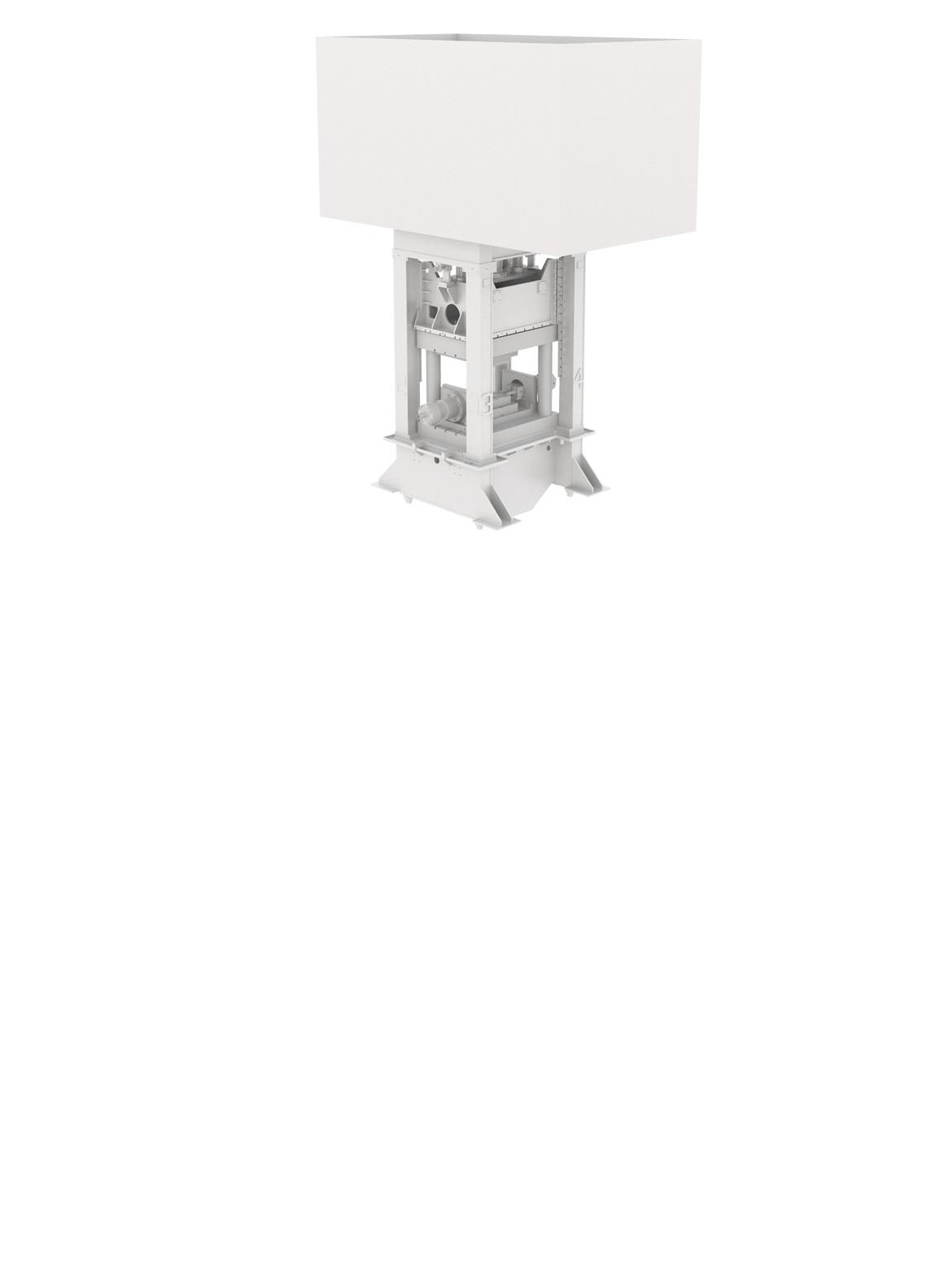

Your Idea

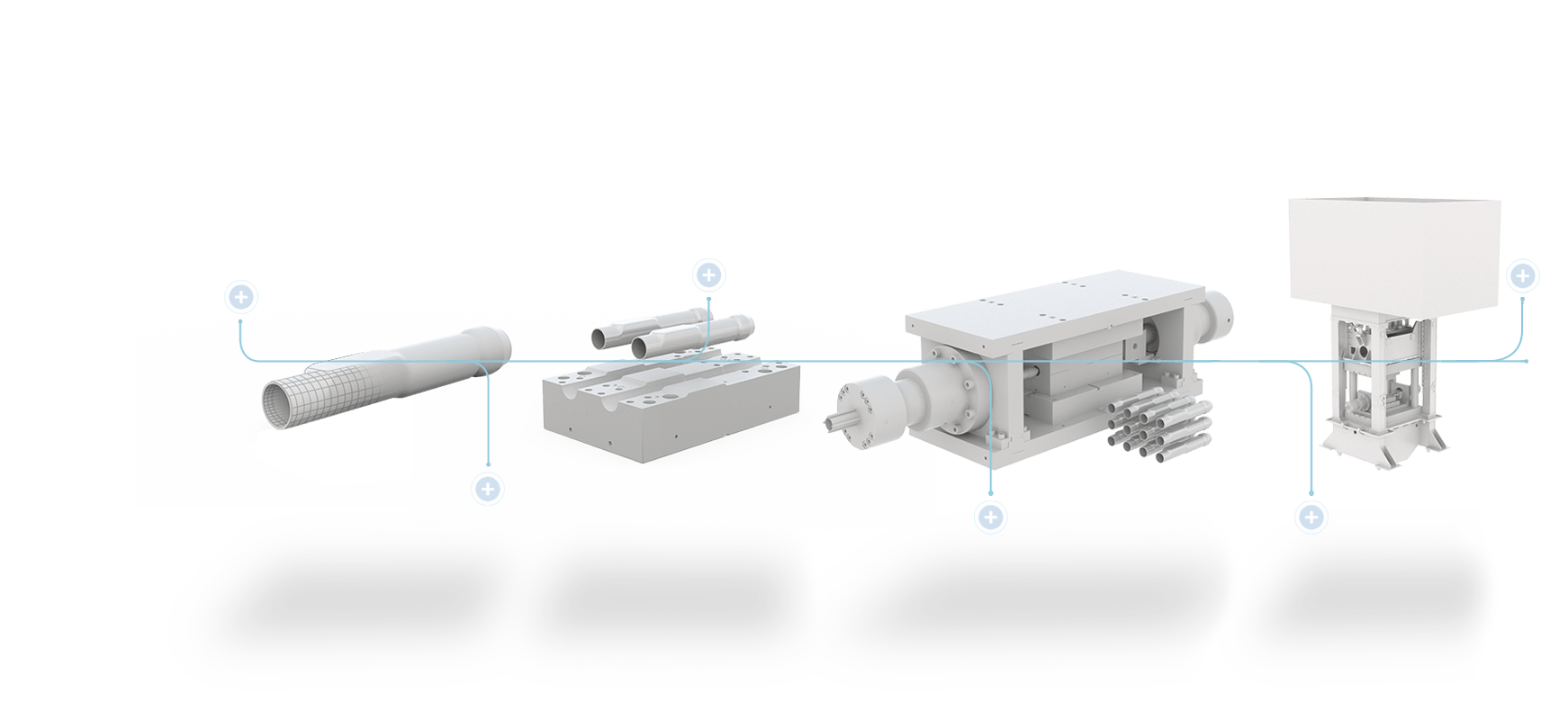

Optimum and individual solutions are benchmarks of our work. Therefore, your idea always is the starting point of our collaboration. Based on your initial considerations, component designs or existing products we support and accompany you along the entire process chain. Our hydroforming experts conduct quick initial analyses and give recommendations on how to achieve the optimum results.