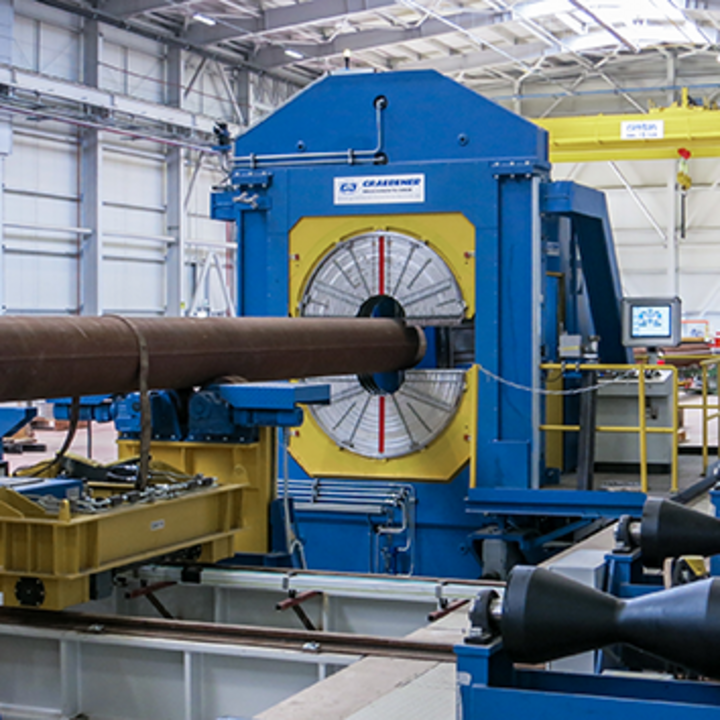

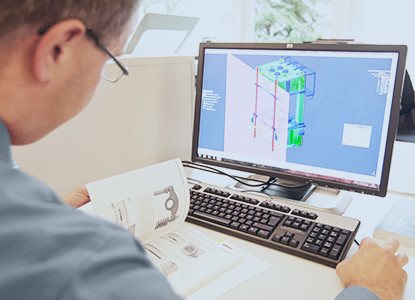

Only the best technology is applied for an optimum result. Our CNC controlled technology for increased wall thickness automatically considers the ovality at the pipe ends thus ensuring a constant web processing. This is made possible by an electronic measuring system which measures the ovality of the pipe to the center throughout the entire pipe circumference. This way, deviations from the theoretical pipe center can be displayed graphically.

Your Graebener® machine generates a set of data for each pipe end which is processed in the CNC software for the automatic tool correction. This way, even the weld seam does not need to be considered during the machining process since the seam is detected as unevenness by the intelligent control software based on the exact measuring data and compensated in the machining process.

In addition to this, the electronic measuring system – in case of the 2-side machine concept – allows the automatic measuring of the pipe length and hence the possibility to adapt the pipe to an exact length.