The custom machine builder Graebener® Maschinentechnik recently successfully commissioned a circ seam milling machine for the preparation of weld seams on wind tower sections in Portugal. The customer is the company Vieira Alves Metalomecânica, SA. (VAM) located in Alferrarede. Founded in 2004, the family-owned company manufactures metal structures for cement and glass-ceramic production. VAM has also set itself the target of establishing the company as a renowned manufacturer of wind towers in the renewable energy sector.

VAM focuses on the quality of its products, the qualification of its specialist staff and a constant innovation process in its production. Looking for a more efficient and effective process for weld seam preparation on wind tower sections, VAM's production team turned to Graebener®, based in South Westphalia/Germany, which has been the global market leader for circ seam milling machines for many years. Together, VAM and Graebener® developed a solution concept that could be optimally integrated into the existing production line at the lowest possible investment costs.

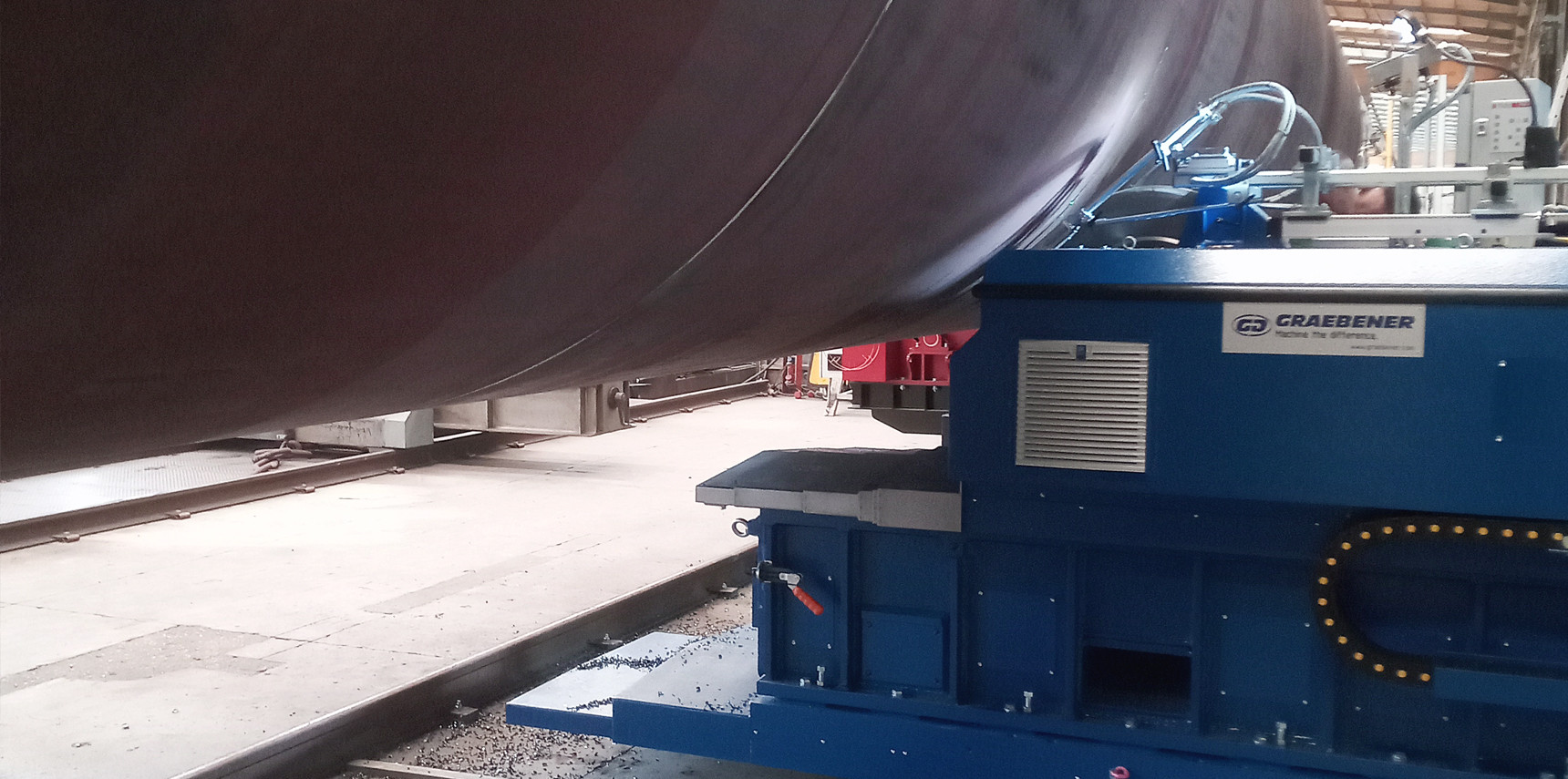

Circ seam milling machines are usually transportable machines and are positioned on the weld seam to be processed by crane or on rails. At VAM, the process is reversed. Instead, the approx. 30 m long wind tower sections pass the fixed positioned circ seam milling machine. By means of movable turning devices, the section, which has already been welded from the inside by submerged arc welding, is positioned in such a way that the seam to be processed is located directly in front of the milling head. This allows safe and at the same time very fast positioning on the approx. nine circumferential seams of the respective sections - without any crane handling. An additional support which is positioned crosswise to the section moves the circ seam milling machine forwards and backwards. Diameters from 1.3 m to 5.5 m can be processed up to a milling depth of 100 mm. To ensure that the wide movable pipe turning devices can also pass the circ seam milling machine, it is moved into a parking position.

Thanks to the mechanical weld seam preparation, the original manual processing with gouging, grinding processes and subsequent cleaning is no longer necessary. Due to the fact that only the external tack weld seam is milled to the root of the internal weld seam with the circ seam milling machine, the existing welding procedure specifications (WPS) do not need to be changed. In addition, the very precise edges of the seam preparation now allow an automated welding process.

VAM states that, since the Graebener® circ seam milling machine is being used, two sections of 30 m length with 9 circumferential seams each can be processed per shift. Previously, more than two shifts were required for the same work, and this in very extreme working conditions. VAM increased the efficiency of this process by more than 50%, while improving working conditions, saving on labor costs and increasing quality.

Return to news overview