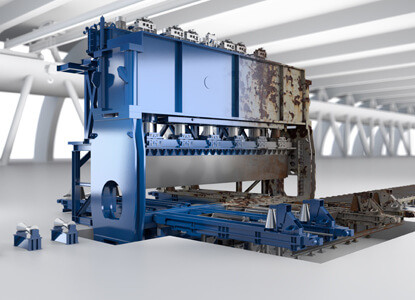

4-Column Press

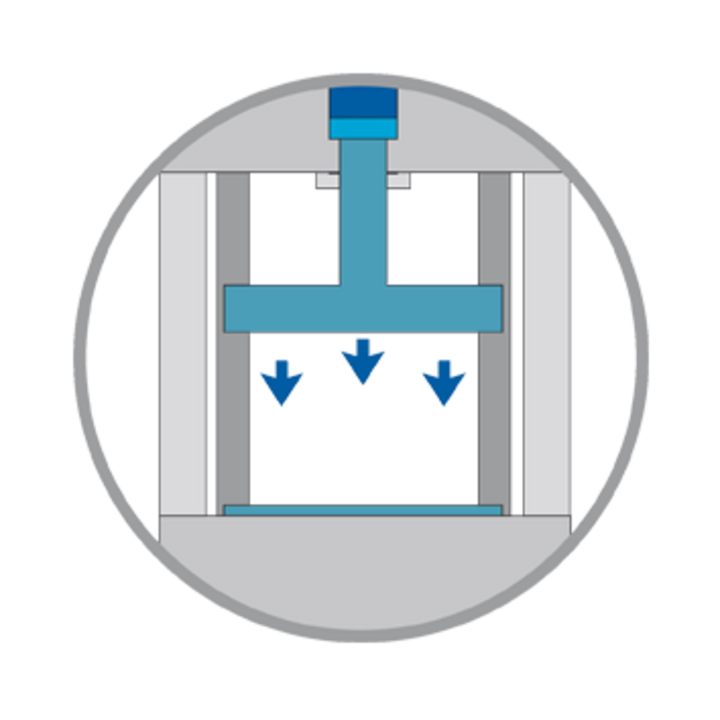

The 4-column press is perfectly suitable for the integration into a hot forming line. Upper and lower traverse are connected by means of pre-tensioned tie rods. This design offers comprehensive advantages: on the one hand the press frame is very solid and offers an optimum deflection compensation. On the other hand, this design allows easy access to the tool area for the operator from all four sides. Therefore, the components can also be processed automatically without any problems.

4-column presses are used for a wide range of application. They are standardized for closing forces of 630, 800, 1,000, 1,200, 1,500, 1,700, 2,000, 2,500, 3,500 and 5,000 tons.